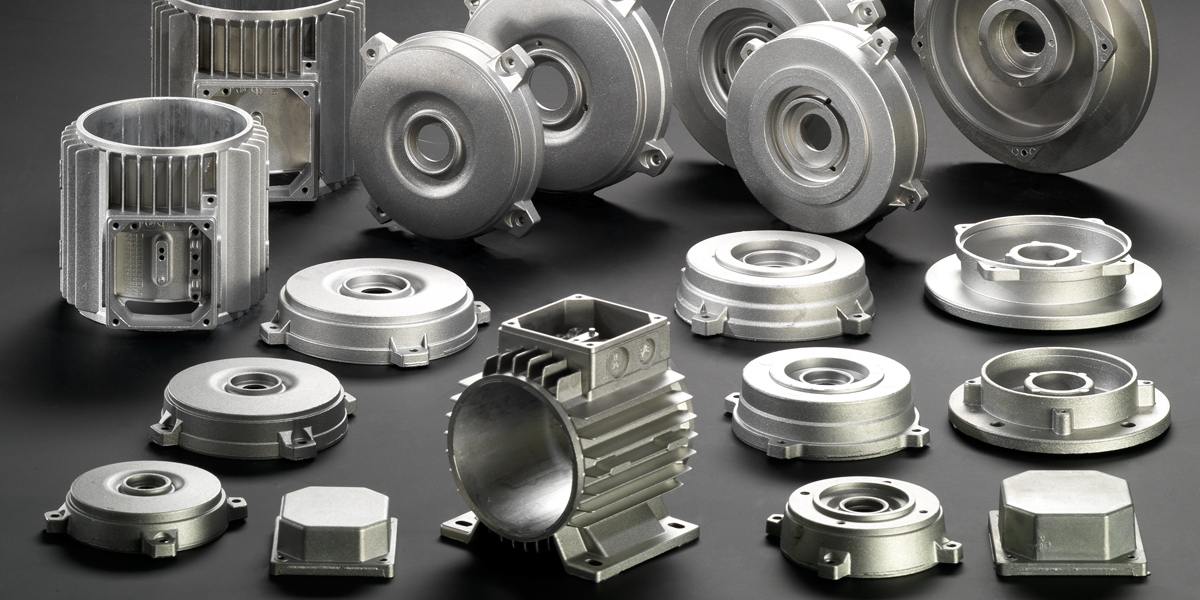

Diecasting in Malaysia has emerged as an important industry, playing a substantial role in the country’s production and industrial industries. Known for its effectiveness and precision, die casting entails injecting liquified metal into mold and mildews to produce parts with high dimensional accuracy and phenomenal surface area quality. This process is widely utilized throughout industries such as automotive, electronic devices, aerospace, and consumer goods. In Malaysia, the die casting industry has actually gotten importance due to the nation’s critical place, experienced workforce, and focus on advanced manufacturing innovations. With an enhancing need for light-weight, durable, and economical parts, Diecasting continues to be a driving force behind Malaysia’s commercial development and worldwide competitiveness.

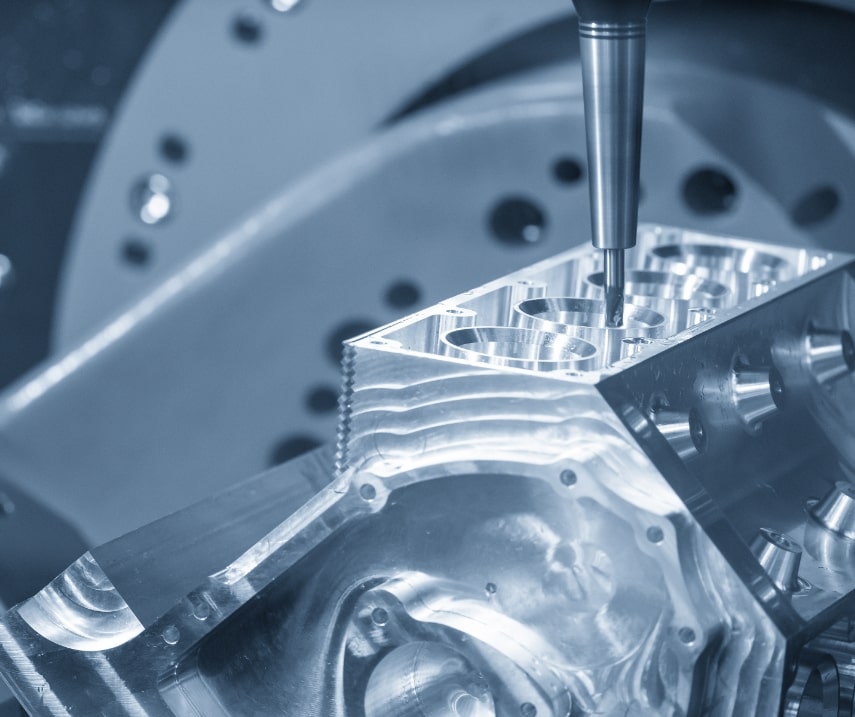

Among the key reasons die casting has actually grown in Malaysia is its application in the automotive industry. As one of the biggest contributors to the Malaysian economy, the automobile field counts greatly on die-cast elements for engine parts, transmission systems, and structural parts. Aluminum Diecasting, specifically, is popular for producing lightweight and corrosion-resistant components that enhance car efficiency and fuel efficiency. Business in Malaysia have actually embraced innovative Diecasting modern technologies, such as high-pressure and vacuum Diecasting, to meet rigid quality requirements needed by international vehicle suppliers. This concentrate on advancement has actually made it possible for Malaysian die casting firms to become crucial providers in the global automobile supply chain.

Past the vehicle sector, Diecasting in Malaysia is pivotal to the electronics and telecommunications industries. The nation, called a hub for electronic devices making, requires high-precision parts for products such as smart devices, computer systems, and interaction gadgets. Diecasting is the recommended method for creating elaborate parts like heatsinks, adapters, and housings due to its ability to supply intricate shapes with remarkable thermal and electric homes. Malaysian manufacturers have leveraged cutting edge tools and stringent quality control procedures to satisfy the needs of global electronics giants. This synergy between Diecasting and electronics production has added dramatically to Malaysia’s reputation as a leader in modern manufacturing.

Sustainability and performance are increasingly becoming centerpieces for the die casting industry in Malaysia. Manufacturers are buying eco-friendly practices, such as reusing scrap steel and reducing energy intake during the spreading procedure. Advanced simulation software application is made use of to enhance mold and mildew layouts and minimize material waste, boosting both cost-effectiveness and sustainability. The use of light-weight products, such as magnesium and light weight aluminum alloys, aligns with international initiatives to decrease carbon discharges, specifically in the automobile and aerospace markets. By adopting environment-friendly manufacturing methods, Malaysian Diecasting business are not only fulfilling governing needs yet also positioning themselves as accountable gamers in the global market. For more information please visit here www.senadiecasting.com.my/

Malaysia’s die casting industry benefits from a strong ecosystem of research study, development, and cooperation. Collaborations between producers, colleges, and government agencies have driven advancement and skill advancement within the market. Programs focused on advanced manufacturing modern technologies, such as automation and robotics, are gearing up the labor force with the competence needed to stay affordable in a quickly progressing international market. Additionally, the government’s support through policies and motivations, such as tax obligation breaks and gives, has actually motivated financial investment in advanced facilities and study efforts. These initiatives have actually strengthened Malaysia’s placement as a local center for Diecasting and advanced production.

Diecasting in Malaysia is an essential market that continues to sustain the country’s economic and commercial development. Its applications in vehicle, electronic devices, and various other sectors underscore its significance in generating high-quality, affordable elements. By accepting development, sustainability, and collaboration, Malaysian Diecasting companies are well-positioned to satisfy the difficulties of a progressively affordable international market. As sectors around the world demand light-weight and precision-engineered parts, Malaysia’s Diecasting sector is poised to play a pivotal duty in shaping the future of manufacturing. With a concentrate on top quality, performance, and ecological duty, Diecasting stays a keystone of Malaysia’s commercial success.